Why Fasteners are Important:

- Corrosion Resistance: Essential for withstanding harsh environmental conditions and extending the lifespan of infrastructure components.

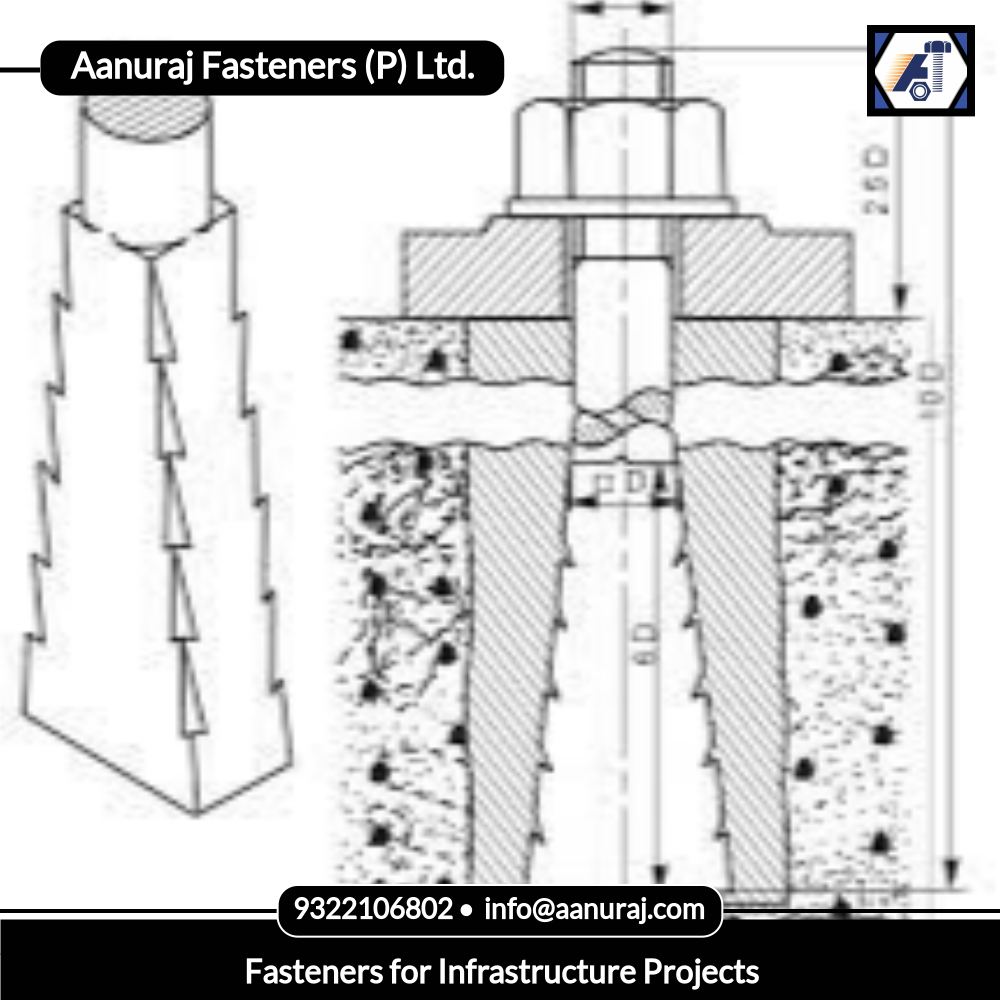

- High Strength: Necessary for supporting heavy loads and ensuring the structural integrity of constructions.

- Durability: Long-lasting fasteners reduce the need for frequent replacements and maintenance.

- Safety: Reliable fasteners ensure the safety of structures, preventing failures and accidents.

- Compatibility: Fasteners must be compatible with various construction materials, such as steel, concrete, and composites.

- Ease of Installation: Simplifies the construction process and reduces labor costs.

- Weather Resistance: Fasteners should withstand extreme weather conditions, including temperature fluctuations and moisture.

- Compliance: Adhering to industry standards and regulations ensures the quality and safety of infrastructure projects.

- Versatility: Suitable for a wide range of applications, from bridges to buildings to road barriers.

- Cost-Effectiveness: High-quality fasteners reduce long-term maintenance costs and improve overall project efficiency.

Important Grades of Fasteners for the Infrastructure Industry:

- 304 Stainless Steel: Offers good corrosion resistance and strength, suitable for general infrastructure applications.

- 316 Stainless Steel: Provides superior corrosion resistance, especially in marine and coastal environments.

- High Tensile Steel: Used in applications requiring high strength and load-bearing capacity.

- Galvanized Steel: Provides additional corrosion resistance through a protective zinc coating.

- Duplex Stainless Steel: Combines high strength with excellent corrosion resistance, ideal for demanding environments.

- Super Duplex Stainless Steel: Enhanced resistance to stress corrosion cracking and pitting, suitable for harsh conditions.

- Hot-Dip Galvanized Fasteners: Increased durability and protection against rust, suitable for outdoor applications.

- Alloy Steel: High strength and toughness, used in critical structural applications.

- Weathering Steel: Forms a stable rust-like appearance, eliminating the need for painting and providing long-term corrosion resistance.

- Carbon Steel: Economical and versatile, used in a wide range of infrastructure applications.

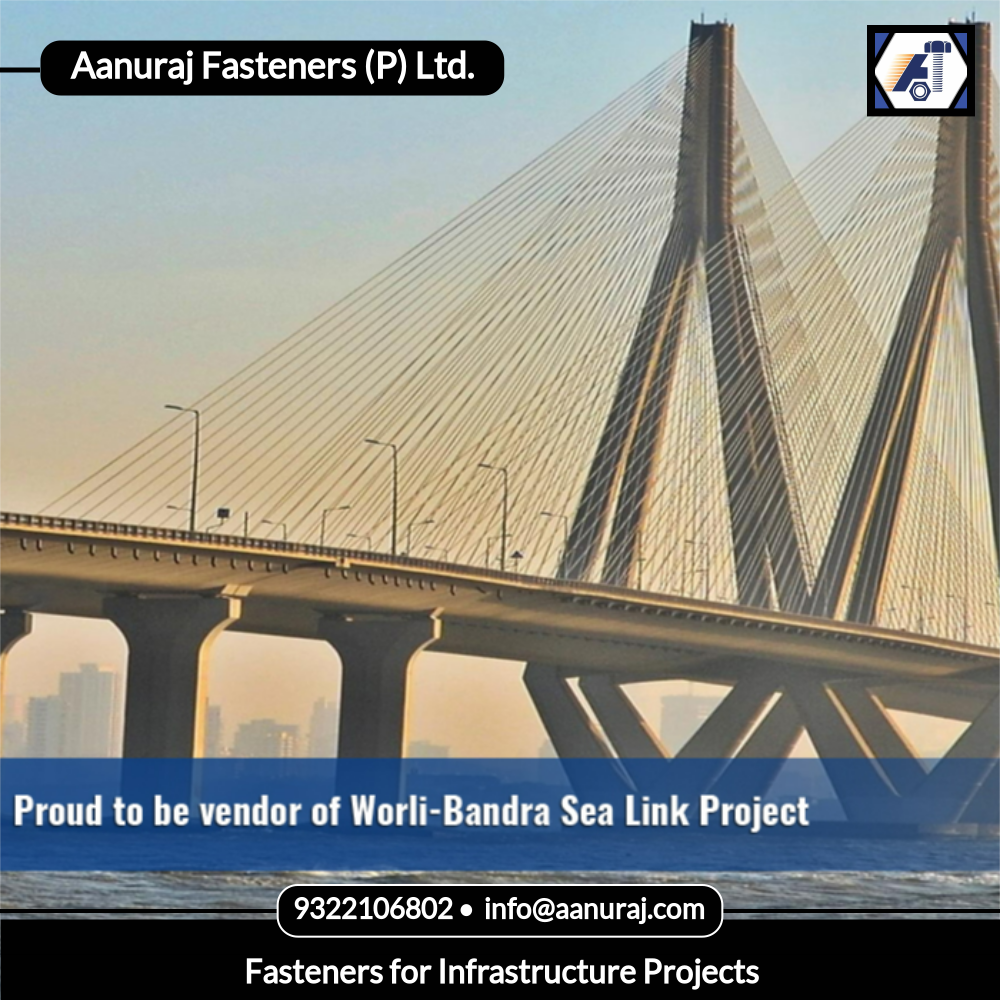

Applications:

- Bridge Construction: Ensuring the stability and safety of bridge structures.

- Building Foundations: Providing strong and reliable connections for building supports.

- Road Barriers: Securing crash barriers and ensuring road safety.

- Railways: Fastening rail tracks and components securely.

- Tunnels: Supporting structural elements in tunnel construction.

- Highways: Connecting components in highway construction and maintenance.

- Marine Structures: Withstanding corrosive environments in docks, piers, and offshore platforms.

- Power Plants: Reliable fastening in energy infrastructure.

- Water Treatment Plants: Corrosion-resistant fasteners in water processing facilities.

- Industrial Facilities: Durable and strong fasteners for various industrial applications.

Keywords: #InfrastructureFasteners #CorrosionResistance #HighStrength #ConstructionSafety #DurableFasteners