Importance of Fasteners in the Wind and Solar Power Industry

Why Fasteners are Important?

- Corrosion Resistance: Fasteners must resist corrosion due to exposure to the elements, ensuring long-term durability.

- Strength and Durability: High-strength fasteners are essential to withstand high winds and structural loads.

- Weather Resistance: Fasteners should endure extreme weather conditions, including UV radiation, rain, and snow.

- Temperature Resistance: Fasteners must maintain integrity across a wide range of temperatures experienced in outdoor environments.

- Vibration Resistance: Fasteners must be able to resist loosening from vibrations caused by wind and mechanical operations.

- Ease of Maintenance: Quality fasteners allow for easy maintenance and replacement, minimizing downtime.

- Safety: Reliable fasteners ensure the safe operation of wind turbines and solar panels, reducing the risk of accidents.

- Environmental Impact: Fasteners must be eco-friendly, with minimal environmental footprint during production and use.

- Compatibility: Fasteners must be compatible with various materials used in wind and solar power systems.

- Compliance: Using industry-standard fasteners ensures compliance with safety and quality regulations.

Important Grades of Fasteners for the Wind and Solar Power Industry:

- 304 Stainless Steel: Offers good corrosion resistance and strength, suitable for general applications.

- 316 Stainless Steel: Provides superior corrosion resistance, especially against chlorides and harsh environments.

- Duplex Stainless Steel (2205): Excellent strength and resistance to stress corrosion cracking, ideal for harsh environments.

- Super Duplex Stainless Steel (2507): High resistance to pitting and crevice corrosion, suitable for marine environments.

- Inconel 625: High strength and excellent corrosion resistance, particularly in high-temperature applications.

- Monel 400: Good resistance to corrosion by seawater and acidic environments.

- Hastelloy C276: Exceptional resistance to chemical corrosion, ideal for aggressive environments.

- A286 Stainless Steel: High strength and oxidation resistance at elevated temperatures.

- Titanium Grade 5 (Ti-6Al-4V): High strength, lightweight, and excellent corrosion resistance.

- Xylan-Coated Fasteners: Provide additional corrosion resistance and reduced friction, suitable for critical applications.

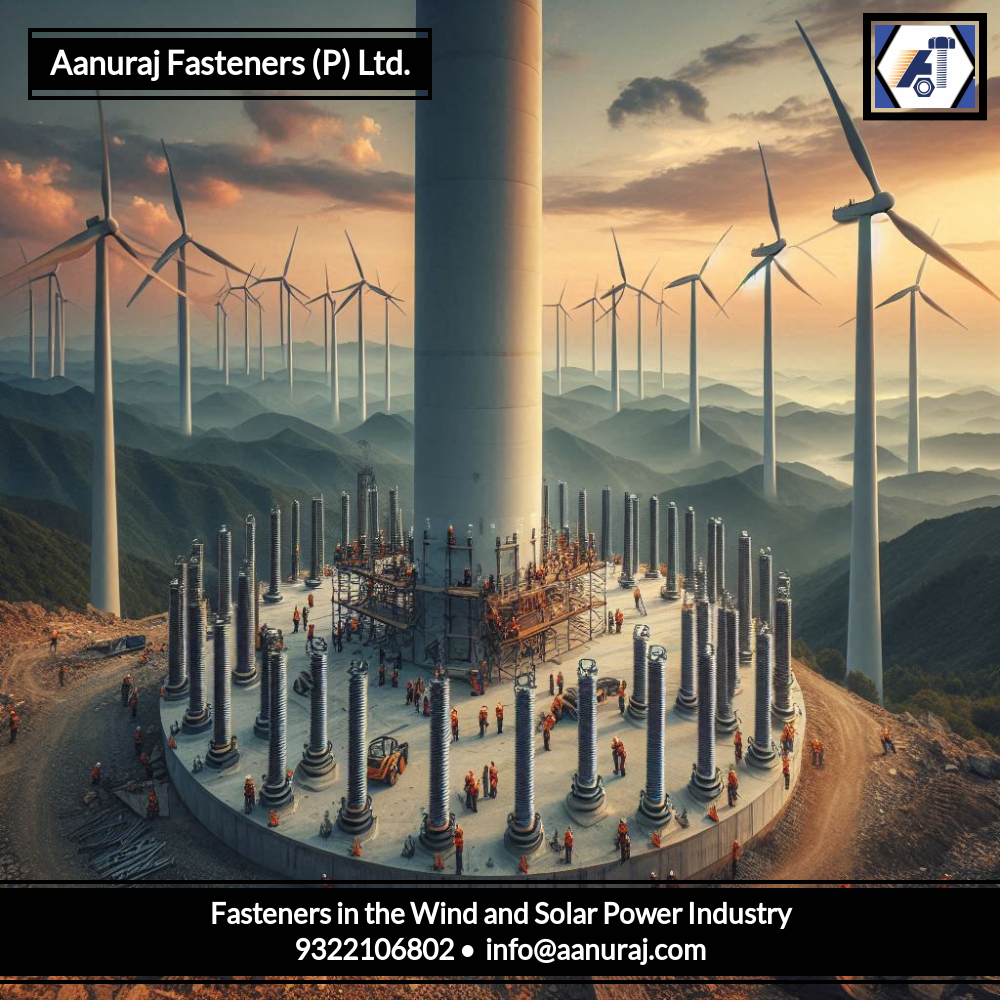

Applications:

- Wind Turbines: Fasteners used in the assembly and maintenance of turbine blades, nacelles, and towers.

- Solar Panels: Fasteners used in mounting systems, frames, and electrical components.

- Structural Components: Ensuring the stability of structures supporting wind turbines and solar panels.

- Electrical Connections: Secure fastening of electrical connections and components.

- Maintenance and Repair: Quick and efficient replacement of worn-out components.

- Piping Systems: Secure connections in pipes transporting fluids in cooling and hydraulic systems.

- Towers and Foundations: Fasteners used in the construction and maintenance of towers and foundations.

- Control Systems: Reliable fastening in control and monitoring systems.

- Battery Storage Systems: Corrosion-resistant fasteners in battery enclosures and support structures.

- Tracking Systems: Fasteners used in the assembly of solar tracking systems.

Keywords: #CorrosionResistance #WindPower #SolarPower #StainlessSteelFasteners #RenewableEnergy